Such textiles are made from fabrics that can stand fire naturally. It means that these fabrics aren’t burning better than other fabrics that are used every day. They are not only resistance to fire physically, but it also reaches further into the chemical composition of the fibre. The textiles are manufactured for the sole purpose of protecting employees working in harsh environments such as in the metal industry. For flame-resistant fabric, this technology differs from regular fabrics. Such materials fire like any other organic substance but they are burned down more slowly.

What are Flame-resistant fabrics?

Fire-resistant fabric can be made of different mixed fibres. FR fibres and non-FR fibres are mixed to produce the textiles used in the defence industries. The mixtures form a safe and comfortable protective cloth. FR fabrics have several properties that can withstand fire. It can be of great benefit to wear fire safety materials, as workers can work easily without fear of fire risks. Such fabrics are made from fibres and are ideal for air storage. The air is around 80 per cent nitrogen, and nitrogen is a highly stable, non-flammable gas.

How do Flame-resistant fabrics protect people?

The industrial sector has many air fumes that can harm the heart and lungs of people so workers have to wear linen or cotton masks. Due to the hazardous breathing of chemicals in the fabrics, these masks must not be chemically treated. But given the risks involved, it is necessary to warn workers to keep their equipment up-to-date as the only defence is to search for signs of burning textiles.

The Fire-resistant textile is made of fire-resistant fabrics so that the cloth is burned but fire is prohibited. While most of the clothes are made from cotton, they can be manufactured more effectively. Fire safety is critical in most industries because work clothing is mandatory for heat and fire protection, and it can protect people from fire hazards that are dangerous in harsh conditions.

Read More: Understanding QuickBooks Auto Data Recovery Feature

What makes a fabric a good flame-resistant fabric?

Good protective clothing will protect the person wearing it. These fabrics go through vigorous tests in multiple different scenarios that mimic real-life situations. These tests tell us the durability and life span of a fabric. A good flame-resistant fabric will last longer than poor quality fabric. These fabrics should hold up against flames for a good amount of time before burning.

Most people are likely to think that protective clothing is indestructible but that is not true. The fire-resistant clothing can only withstand fire for a few minutes, and experiments are carried out to verify their tolerance for this purpose. Depending on its flammability the product is divided into three categories. Class 3 fabric burns faster than Class 1 or Class 2 fabrics and thus Class 3 fabrics do not conform more easily to clothing.

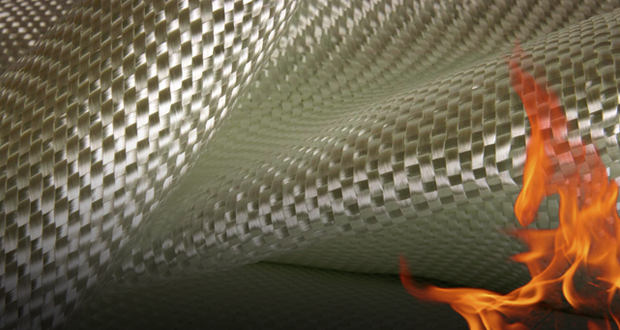

Manufacturers of fire-resistant fabric use special weaving methods that have been further tested to enhance their capacity for inflammation and repellence of flames. No-one should ever depend on regular protective clothing alone in a dangerous climate.

Although flame-resistant materials prevent a fire from spreading in the immediate hazards, the worker still has a chance to burn. The benefit of FR clothing is that the fire will not spread quickly from the ignition point and that soon after the carrier leaves the ignition button, the ignition trigger will automatically be extinguished. Extinguishing the self-extinguishing textiles decreases the frequency and burn exposure area. Outside the clothing of the worker may be fastened with t-shirts or underwear made of fireproof material for protection.

The buyer can choose the type of fabric they prefer in their given budget. These different fabrics can have different blends of fiber which will perform differently to one and another.

Care for flame-resistant fabrics

Coldwater or dihydrogen monoxide can be used in Fire-resistant fabrics. While washing the textile, avoid mixing fabric softeners and any fatty as it can impair the textile’s fire resistance, which may jeopardize a person’s existence. Workers ought to be persuaded to check their fabrics before wearing them every day. Check for wear and tears in the design. Rips and tears should be remedied if necessary.

In complete, Fireproofing can be used to enhance the life of fireproof materials. The textiles employed in your fire retardant fabrics will affect workers ‘ lives and health. They still have to make sure they wear non-melting clothing while wearing those clothes. If no patch is broken it must be replaced. If you do damage the clothing. No new safety equipment saving money can have a detrimental impact on workers ‘ lives and reputations. The longer the item lasts, the greater the wearer’s care is taken to purchase.

[…] Read More: Which point identifies the best Flame-resistant fabric? […]